18122393143

18122393143

计算标准:美标、厂家标准

分析软件:Staad

分析类型:轴系振动分析(Misalignment and Vibration Analysis)

分析目标:

(1)Verification of the natural frequencies of the foundation;

(2)Verification of the dynamic stiffness limits;

(3)Verification of the dynamic behaviour of the foundation with respect to unbalance forces;

(4)Misalignment verification;

(1)基座固有频率分析;

(2)基座动刚度分析;

(3)基座在不平衡力作用下的动力响应分析;

(4)轴系偏差分析;

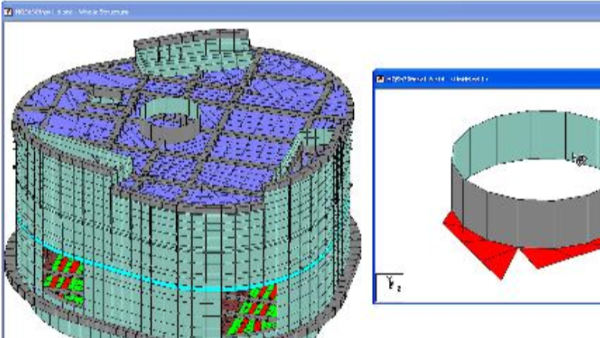

1. F.E. MODEL DESCRIPTION(有限元模型)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_125.jpg)

(a)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_127.jpg)

(b)

Fig.1.MODEL DESCRIPTION

2. LOADS(荷载)

2.1 DEAD WEIGHT LOADS(自重)

Inertial masses are deduced from dead weight loads as stated on foundation.

由基座的自重推导出惯性质量。

2.2 UNBALANCE LOADS(不平衡力)

Unbalance loads for the vibration analysis are applied at the bearing locations pictorially shown in the drawing below. Numerical values can be found on the code.

不平衡力作用的位置如下图所示,为基座的轴承座位置。不平衡力大小可由规范中平衡品质换算得到。

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_129.jpg)

Fig.2.BEARING LOCATIONS

3. DESIGN FOR NATURAL FREQUENCIES

According to relevant regulation, significant natural frequencies must lie outside the intervals [9 Hz, 11Hz], [45 Hz, 55 Hz] for LP turbine, generator and gear box LS shaft, and must lie outside the interval [18.675 , 22.825], [93.375 Hz, 114.125 Hz] for HP turbine and gear box HS shaft.

相关资料显示,汽轮机低压缸、发电机、齿轮箱LS轴的有效固有频率一般位于 [9 Hz, 11Hz], [45 Hz, 55 Hz] ,汽轮机高压缸、齿轮箱HS轴的有效固有频率一般位于[18.675,22.825], [93.375 Hz, 114.125 Hz],所以基座的固有频率必须避开这些区间,以免发生共振。

Table.1 Not allowable foundation natural frequencies

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_131.jpg)

In addition, it is not allowed that the foundation natural frequencies coincide with following:

Table.2 Not allowable foundation natural frequencies*

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_133.jpg)

*In case it can not be avoided that the foundation natural frequencies coincide with frequenciesabove it has to be checked that the resulting effective vibration velocities at the load points will remain below 7,5mm/s.

*如果不能避免基座固有频率与上述频率重合,则必须保证荷载作用点处的有效振动速度保持在75mm/s以下。

Most representative modes are shown in the following figures and the corresponding mode values can be seen on the accompanying table. The total mode effective mass is greater than 96,53% of the total mass and significant modes lie lower 27,96Hz. The operating range modes are highlighted in grey and not allowable foundation natural frequencies are highlighted in blue.

下表为计算所得基座的模态,同时给出了各模态对应的频率。96.53%有效质量对应的模态,频率均于27.96HZ。灰色代表设备的运行频率表,蓝色代表基座应避开的频率。

Table.3 Calculated modal frequencies and massparticipation factors

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_135.jpg)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_137.jpg)

Fig.3.Most significant mode shapes (frequency – direction – mass participation)

On the figure above the Mode 3 and Mode 5 are not presented due to negligible mobilized masses participation in these modes.Frequency for self excited oscillation [20.0 – 28.33Hz ± 5%] can be seen to coincide with natural frequencies.

模态3和模态5参振质量较小,可以忽略。自激振荡频率[20.0-28.33Hz ± 5%]与固有频率一致。

4. DESIGN FOR DYNAMIC STIFFNESS

4. 动刚度分析

Maximal horizontal and vertical dynamical flexibilities at each bearing location have been calculated for the operating frequency. Resulting values are below the threshold limits 0.10mm/MN for the vertical and horizontal flexibility (it is an equivalent of the value 1x107kN/m for the vertical and horizontal stiffness given in the code).

运行频率下各轴承位置的最大水平和竖向动刚度如下表所示,结果值均低于限值0.10mm/MN。

These results are represented in the table below.

Table.4. Calculatedhorizontal and vertical dynamic flexibility values(mm/MN)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_139.jpg)

5. DESIGN FOR SHAFT LINE EMERGENCY UNBALANCE

5. 紧急状况下轴系平衡分析

Dynamic behaviour of the foundation against vibration is controlled by ensuring that the effective vibration velocity at bearing locations for the operating frequency satisfies the requirement of the code : maximum effective vibration velocity < 3,8 mm/s.Maximum effective vibration velocities are below this limit,as shown in Table.5

用控制有效振动速度的方式来确保轴系振动相应满足规范要求,最大有效振动速度应控制在3,8 mm/s以下。本例中有效振动速度均满足要求,如表5所示:

Table.5.Maximum effective vibration velocities and limit

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_149.png)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_147.jpg)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_145.png)

In addition, the effective vibration velocity at the load points for the frequency for self excited oscillation has been verified to meet manufacturer requirement: maximum effective vibration velocity < 7,5 mm/s,as shown in Table 6.

另外,验证了轴承座处的自振频率下有效自振速度均小于7,5 mm/s,能够满足制造厂要求,如下表6所示。

Table.6..Maximum effective vibration velocities (self excited oscillation) (mm/s)

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_151.png)

6. MISALIGNMENT

6. 轴系偏差

6.1 DISPLACEMENT OF SUPPORT SURFACES

6.1 支承面的位移分析

The calculated foundation deflection is based on the foundation loads that are applied after initial turbine-generator alignment, e.g., normal operational loads: force from torque, vacuum load and piping load. The displacement of the supported surfaces has to remain in the limits according to the code.

基座挠度的计算是基于设备对中后对基座的荷载,如正常运行荷载:扭矩、真空力和管道荷载。根据规范,支承面的位移必须满足限值要求。

6.1.1 Inclination of package support area

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_153.jpg)

Fig.4. Support points

Table.7. Inclination of package support area

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_155.png)

6.1.2 Vertical differential deformation of the support points to each other

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_157.jpg)

Fig.5. Support points

Table.8.Vertical differential deformation

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_159.png)

艾三维技术信息技术有限公司专注BIM咨询|软件出售|BIM平台研发|建模出图|BIM培训|工程动画

咨询热线:4000333136 微信:18122393143

![STAAD.Pro | 动力设备基础分析[美标] STAAD.Pro | 动力设备基础分析[美标]](/resource/images/5a3d69c1677940c7bba63ee3310cf78d_161.png)

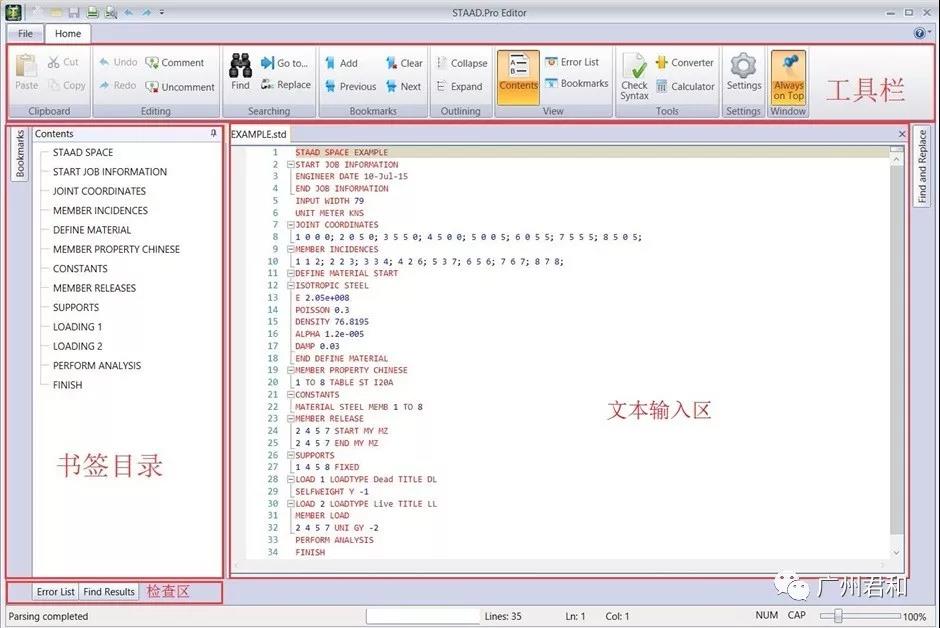

STAAD.Pro具有最友好的的用户界面,可视化的工具,强有力的分析以及设计功能,既可以做有限元的分析也可以做结构动态分析;既可以对普通工程进行设计也可以对超高层的建筑物、管路、化工厂车间、隧道、桥梁、反应堆中的钢构、混凝土、木材、铝以及冷轧钢(cold-formed)进行模拟、分析、设计和结果验证...

【功能详解】STAAD.PRO 可以使用内置的文本编辑器快速的建立复杂模型。STAAD.Pro 内置文本编辑器可以通过点击程序工具栏上按钮打开,文本编辑器主要由下拉菜单,工具栏和文本输入区三部分组成,如图所示。